Robotics has been part of industry and society since the early 1940s when Robert Asimov a fictional writer wrote his book titled the Three Laws of Robotics. With this book’s publishing, the era of robots had begun. Back then, robots were viewed as a threat to humanity. Robots were seen as a threat to life and also towards livelihoods when they started appearing in the industries.

From then on, study and research into universal robotics have progressed and are now married into technology and are an integral part of many aspects of life and industry.

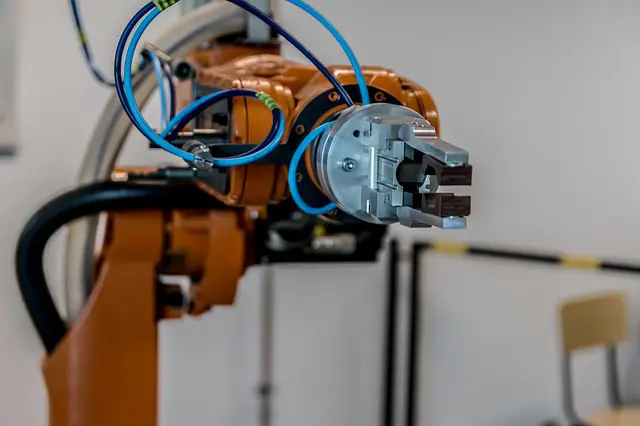

As research deepens and technology advances companies such as Universal Robots have created collaborative robots for use in industry. Collaborative robots are robots that compatibly work alongside human staff on the factory floor.

With the growth in the industry, comes different robot manufacturers seeking to help automate the production process.

Why trust Universal Robots for your collaborative robots?

Professionalism

Founded on a background of research, Universal Robots is a highly professional organization. They produce high quality, easy to use robots that create value in the production process.

Expertise

With over 23,500 collaborative robots sold worldwide by this organization, you can trust in their ability to help grow your production process through the incorporation of collaborative robots. Their people are highly trained robotics engineers who can capably train any of their clients in the setting up and use of their cobots.

Safety

Safety in the workplace is one of the biggest factors hindering the adoption of robots in the industry. Universal Robots have developed and patented a technology used in their robots to detect the presence of human beings and reduce the intensity of its activities thus making it safe for the human partner to be around or near the robot.

Technology

In addition to its patented safety technology, Universal Robots capably deploys technology to monitor its robots remotely and offer support to its customers in real-time. Its collaborative robots use an easy to understand and use the program and can be easily deployed to different tasks.

Applications of Collaborative robots in different industries

Technology and electronics

This industry requires high levels of accuracy, precision, and repeatability. Relying on human staff alone is likely to lead to boredom and errors. This will in turn lead to the production of low-quality end products.

Robot use in this industry ensures that all components of the products under production are correctly assembled into the product. This ensures that the end product is high quality and will do well when presented to the market.

Automotive manufacturing industry

The automotive manufacturing industry is one of the industries that has benefited most from the automation of its processes.

Automotive manufacturing includes numerous components that require to be assembled precisely to form high-quality parts of the automobile. A mistake in the production process could lead to loss of lives in the market which is not good for business.

Automation then is the next best option for auto manufacturers. Collaborative robots ensure that components of the automobile are well fixed for a high-quality product. Highly repetitive manual tasks such as screw driving and tasks that need high-level precision such as engine or brakes placement can be assigned to robots for a high-quality end product.

Medical and Pharmaceutical Industry

Collaborative robots are increasingly gaining a foothold in the healthcare industry. In addition to pharmaceutical manufacturers, collaborative robots are also becoming a mainstay of the OR. Surgeons are using robots in surgery for precision and accuracy and also for less discomfort in their patients.

Pharmaceutical manufacturers like all other manufacturers have a need to automate their processes to reduce costs and produce high-quality products. Robots ensure that pharmaceuticals are produced in highly hygienic conditions and that the ingredients in the medicines produced are accurately and precisely mixed to the benefit of the users. Robot use in the pharmaceutical industry leads to higher precision and high-quality products for the end-user.